Driving the electric revolution boosts the UK’s power electronics, machines and drives industry with £5.75 million investment to help the UK reach net zero.

Over 20 innovative projects aiming to reduce carbon emissions in the transport, energy and industrial sectors are to share nearly £6 million in funding. The funding comes from the driving the electric revolution challenge, part of the Industrial Strategy Challenge Fund delivered by UK Research and Innovation (UKRI).

Reaching net zero

This investment into the power electronics, machines and drives (PEMD) supply chain is vital to making sure that the UK reaches net zero.

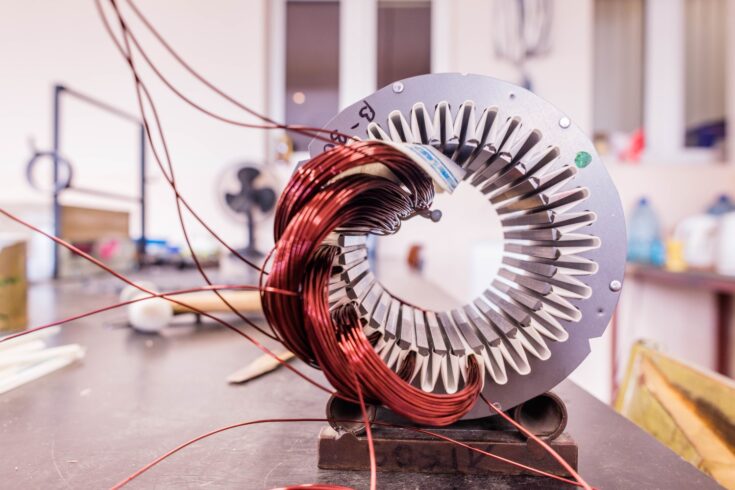

Some or all these technologies can be found in everyday electrical items. From mobile phones to hairdryers and the motors in electric vehicles and trains, PEMD makes them work.

As such, for crucial technologies across sectors from transport to energy to agriculture, net zero will not be possible without advances in PEMD.

Growing UK supply chains

The projects, involving innovative start-ups, universities and some of Britain’s biggest companies, will receive funding from the driving the electric revolution challenge. The money will help grow the UK’s PEMD supply chain and increase manufacturing capability to allow future improvements in productivity, quality, capacity or efficiency.

Spread across the UK from Wales to Scotland and the south-west to north-east England, these projects will last up to nine months and include a project:

- to create rare earth magnets from scrapped loudspeakers

- developing electric hub motors for farm vehicles

- to create a high-performance electric vehicle at a lower cost.

Helping industry

Andrew Hine, Director of GreenSpur Wind Limited, part of a project looking at creating a UK supply chain to build wind turbines said:

The funding from driving the electric revolution will enable us to work with Warwick Manufacturing Group and key members of a growing UK wind supply chain, to design and develop advanced manufacturing processes.

We have developed a highly innovative, rare earth free, permanent magnet generator that will deliver significant cost savings to the offshore wind market. This funding is a critical step in the development of our technology, as it will enable us to demonstrate the capability of the UK supply chain to co-development partners.

Another project led by RAD Propulsion is aiming to create an electric propulsion system with no external propeller blades for use in marine vessels. Their CEO, Clive Johnson said:

This grant from driving the electric revolution challenge will support us in bringing the first of our quality electric propulsion systems, RAD40, to the marine marketplace. We are confident this robust, intuitive and easy to use 40Kw drive, for ribs and powerboats, will revolutionise customer experience.

The driving the electric revolution grant is instrumental by enabling our supply chain and streamlining our production and manufacturing processes and complexities to assist with our goal of bringing a superior product to market in an ambitious timeframe.

Driving the electric revolution challenge director, Dr Will Drury, said:

These projects form a vital part of the UK’s green economic recovery from COVID-19. By focusing on growing the capability of the UK PEMD supply chain and manufacturing we aim to make the UK a global leader in the manufacture of core technologies which underpin electrification. This is crucial in helping the UK reach net zero by 2050.

Further information

Driving the electric revolution launched in 2019 and is funded by an £80 million investment from the Industrial Strategy Challenge Fund, run by UKRI.

Working across all sectors the challenge aims to make the UK a global leader in the manufacture of core technologies which support electrification: PEMD.

We are the catalyst and a main building block to delivering the technology required to achieve net zero. Without PEMD net zero is not possible and without driving the electric revolution, PEMD manufacturing will not happen at scale in the UK.

Funded projects

Trench Clustered Insulated Gate Bipolar Transistor Manufacturing Process Capacity and Productivity Improvement

- Semefab Ltd

- The University of Sheffield

- Eco Semiconductor.

Coolsync

- Supply Design Ltd

- Compound Semiconductor Applications (CSA) Catapult Ltd.

SiC-MAP (Silicon Carbide MOSFET Applications unlocked by PDK)

- Clas-SiC Wafer Fab Limited

- Compound Semiconductor Applications (CSA) Catapult Limited.

Wind Electric Revolution (Winder)

- Magnomatics Limited

- Offshore Renewable Energy Catapult

- Sub-contractors:

- Advanced Manufacturing Research Centre (AMRC), Sheffield

- Wolong ATB Group, Norwich.

Regail – Recovery of Gallium from Ionic Liquids

- S2S Electronics Ltd

- C. Williams Ltd

- Envaqua Research Ltd

- HSSMI Ltd

- Institute of Materials Finishing

- Recolight Ltd.

M-powerd – Manufacturing PSJ GaN Power Devices in the UK

- INEX Microtechnology Ltd

- Compound Semiconductor Applications (CSA) Catapult

- The University of Sheffield.

Development of PEMD for Nuclear Coolant Systems

- Hayward Tyler Limited

- The Nuclear Advanced Manufacturing Research Centre.

Ev-join

- Ansys Granta

- TWI.

Development of Coil Winding and Magnet Assembly Manufacturing Processes for a Ferrite Based Permanent Magnet Generator

- GreenSpur Wind Ltd (Time to Act Limited)

- Warwick Manufacturing Group (WMG).

Development of a PEMD Supply Chain for Off-Road Vehicles

- Perkins Engines Company Limited

- University of Nottingham.

Moto – Supply-chain Talent Accelerating Revolution (Moto-STAR)

- ZF Automotive UK Limited

- Romax Technology

- The Compound Semiconductor Applications (CSA) Catapult

- The University of Sheffield.

Design for manufacture of integrated e-hubs for agricultural vehicles

- Performance Projects Ltd

- ARWAC Ltd

- Printed Motor Works Ltd

- Saga Robotics

- University of Lincoln.

Conmotator: Advanced, Integrated Machines for Efficient Manufacture & Operation

- GE Power Conversion (GEPC), UK

- University of Nottingham.

REAP – Rare-Earth Extraction from Audio Products

- Hypromag Ltd

- European Metal Recycling

- The University of Birmingham.

Wavedrives – Industrialisation Investigation for Wavedrives’ Radical Magnetically Geared Electric Actuator

- Wavedrives Ltd

- University of Bristol.

SOCRATES – Silicon Carbide Transistor Trench Process

- SPTS Technologies Ltd

- Newport Wafer Fab

- Compound Semiconductor Centre

- CSconnected

- Swansea University.

RIFT 10-30 kW EV motor – Manufacturing Readiness and Supply Chain Development (RIFT-marsc)

- RIFT Technology Limited

- University of Warwick.

PMD Rim Drive Propulsion Technology Manufacturing in the Marine Market

- RAD Propulsion Ltd

- iNetic Ltd

- National Composite Centre (NCC).

UK-alumotor

- Ricardo UK Ltd

- Aspire Engineering

- Brandauer

- WMG – University of Warwick

- Phoenix Scientific Industries (PSI) Ltd

- Global Technologies Racing.

Improved Loss Modelling of SMC Components

- SG Technologies Ltd

- Newcastle University.

Gansic

- Custom Interconnect (CIL) Ltd

- Compound Semiconductor Applications (CSA) Catapult.

Top image: Copper wire in a motor (credit: Smoczyslaw/GettyImages)